产品介绍

沙滩椅扶手管机器人自动生产线

Auto production line for beach chair armrest tube

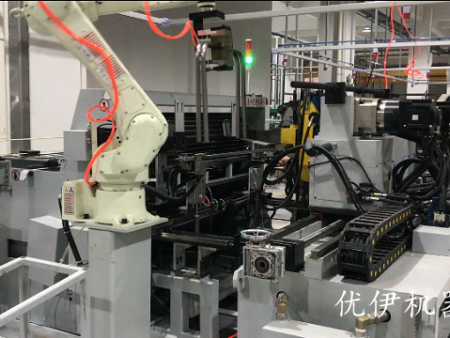

机器人给弯管机上料 Robot feeding tube bender

点上面图片观看视频 Click the picture above to watch video

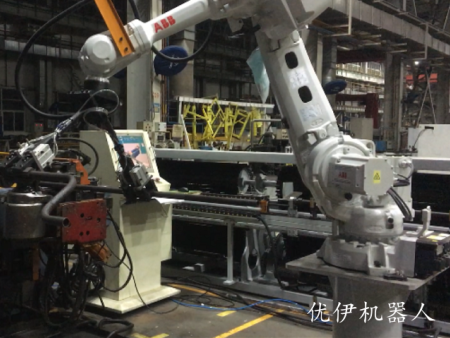

机器人搬运管件到冲孔机

Robot transfer pipe to punching machine

冲孔机对三根管一起冲孔

Punching machine punches three pipes together

机器人卸载成品管件 Robot unloads finished pipe fittings

点上面图片观看视频 Click the picture above to watch video

成品管件 Finished pipe fittings

主要指标:

1)沙滩椅扶手管项目可以节省人工约6人,产生经济效益显著;

2)生产节拍:三根管小于15秒,平均每根管生产节拍小于5秒;

3)管件范围:直径16mm,长度1200mm

4)加工方式:人工将批量直管放入上料机料仓,上料机三根管一组给伺服控制自动弯管机上料;

5)机器人搬运完成对管件到另外一台伺服控制自动弯管机弯曲第二弯;

6)机器人搬运完好的管件到(三根管)到冲孔机;

7)冲孔机对三根管件进行组合冲孔,完成后由下料机器人卸载成品管件到料架;

8)总控采用自适应智能设计,可以随机器人的速度调整生产节拍;

Main Feature:

1) The beach chair armrest tube project can save about 6 people and produce significant economic benefits;

2) Production cycle: three tubes are less than 15 seconds, the average production cycle of each tube is less than 5 seconds;

3) Pipe fitting range: diameter 16mm, length 1200mm

4) Processing method: manually put the batch of straight tubes into the hopper of the feeding machine, and a group of three tubes of the feeding machine feeds the servo-controlled bending machine;

5) The robot transfers the pipe to another servo-controlled pipe bender to bend the second bend;

6) The robot carries intact pipe fittings (three pipes) to the punching machine;

7) The punching machine performs combined punching on the three pipe fittings, and after the completion, the yellow robot unloads the finished pipe fittings to the material rack;

8) The master control adopts adaptive intelligent design, which can adjust the production cycle according to the robot running time.

您如果对这个项目有兴趣可以致电我们:189-6226-9900 (中国), 469-606-9828 (美国)

If you are interested in this project, you can call us: 189-6226-9900 (China),

469-606-9828 (United States)

产品展示 Products

- 弯管机 Tube Bender Solution

- 弯管机自动连线 Tube Bender Auto Cell

- 弯管机配机器人 Robot with Bender

- 切管机 Tube Sawing/Cutting Solution

- 切管机自动连线 Sawing/Cutting Auto Cell

- 自动上料机 Tube Auto Feeding Machine

- 自动冲孔 Auto Punching Machine

- 弯管机上下料专机 Loader/Unloader Sets

- 焊接机器人和自动变位机 Robot welding

- 缩管机 Tube End Forming Solution

- 中空吹塑自动化生产 Hollow blow molding Auto Cell

- 弯管机 Tube Bender Solution

- 弯管机自动连线 Tube Bender Auto Cell

- 弯管机配机器人 Robot with Bender

- 切管机 Tube Sawing/Cutting Solution

- 切管机自动连线 Sawing/Cutting Auto Cell

- 自动上料机 Tube Auto Feeding Machine

- 自动冲孔 Auto Punching Machine

- 弯管机上下料专机 Loader/Unloader Sets

- 焊接机器人和自动变位机 Robot welding

- 缩管机 Tube End Forming Solution

- 中空吹塑自动化生产 Hollow blow molding Auto Cell